SK IE Technology

SK IE Technology■ Changzhou Plant 2 started commercial production, contributing to SK Innovation’s deep change and ESG management

■ Enhancing business competitiveness by establishing a production system capable of providing for approx. 500,000 EVs per year in China

■ Total global production capacity increases to 1.04 billion m2, expected to reach 2.73 billion m2 by 2024

■ CEO of SK IE Technology Roh Jae-sok: “By providing premium separators with high performance and safety, we will contribute to the rapid growth of the global EV market, and continue to improve the production capacity and technology to build an exclusive lead in the market”

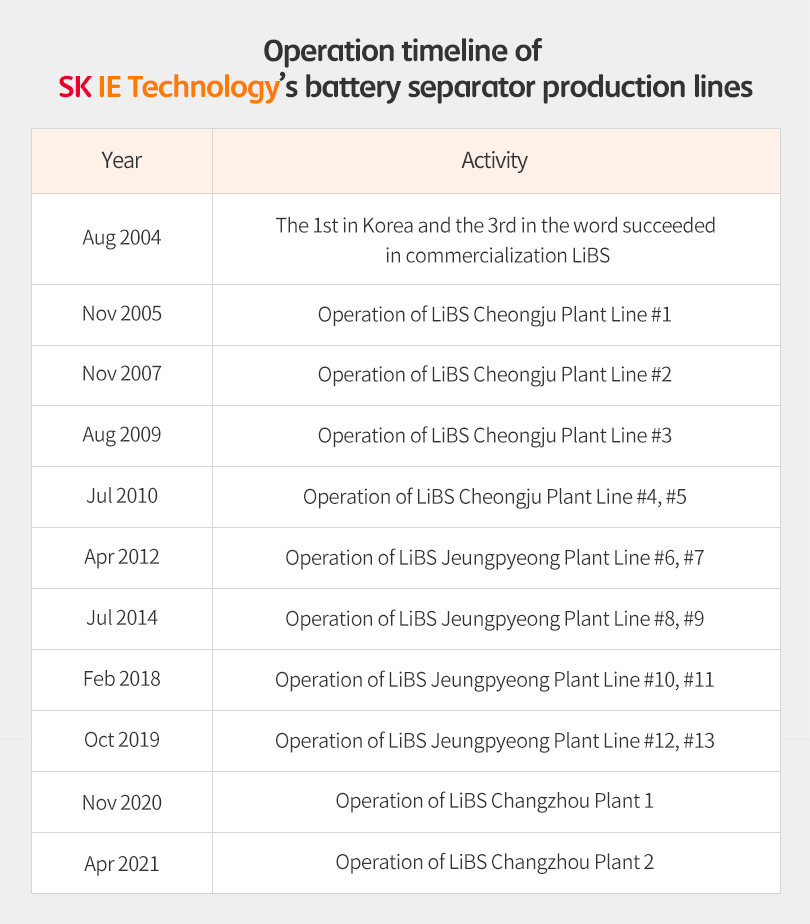

SK IE Technology (SKIET), a material business subsidiary of SK Innovation, announced on the 13th that the LiBS (Lithium-ion Battery Separator) Plant 2 in Changzhou, China, has started commercial production. SKIET’s separator plants in Changzhou is operated by SK Hi-tech Battery Materials Jiangsu, an overseas subsidiary of the company.

Following Plant 1 in Changzhou that began commercial operation last November, SKIET began running Changzhou Plant 2 after five months to accelerate targeting the Chinese EV battery market.

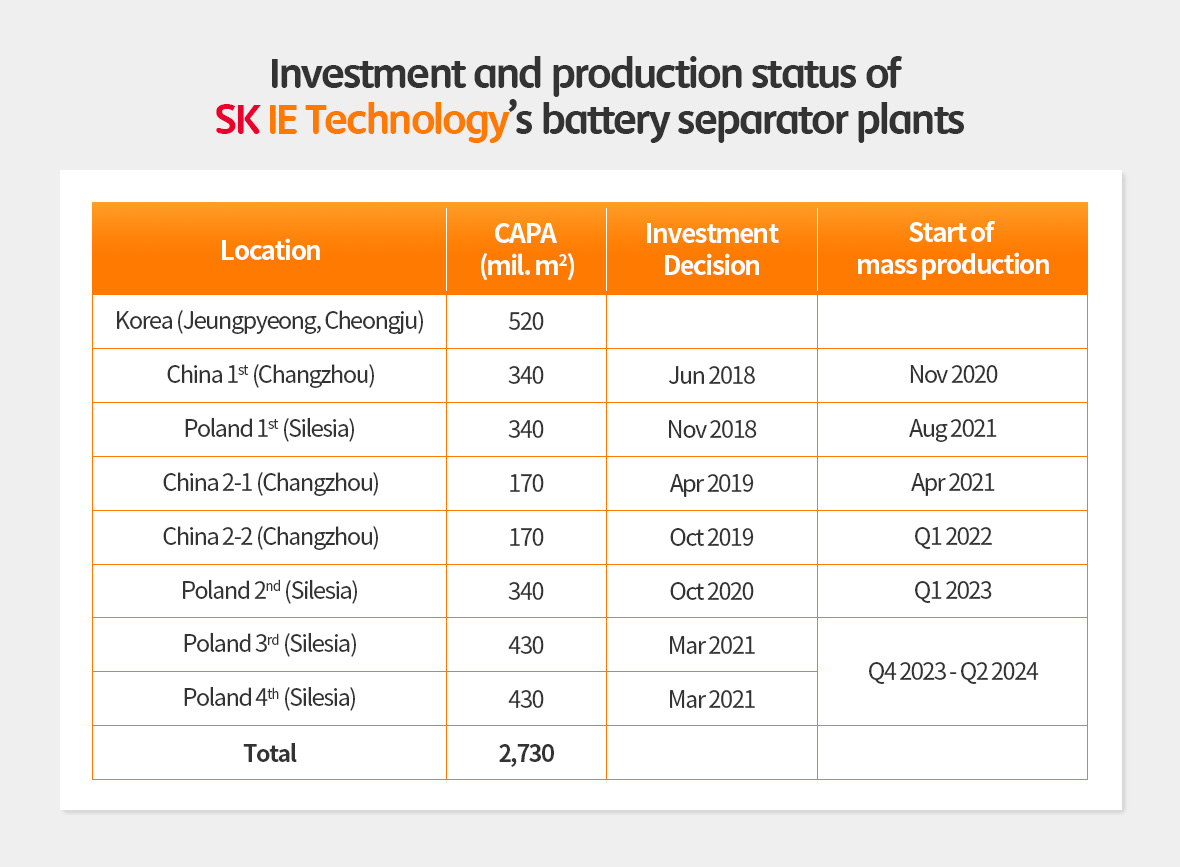

By its partial operation of 170 million m2, which is half of of Plant 2’s total production capacity, SKIET now has 510 million m2 production capacity only in China, including 340 million m2 that of the existing Plant 1. This equals to the capacity of making separators required in approx. half a million high-capacity EVs yearly. The rest of the Plant 2 production line is under smooth preparation, aiming to begin its operation in the first quarter next year.

SKIET has secured 1.04 billion m2 production capacity in Korea, Poland, China, etc., through the operation of Plant 2 in Changzhou. This is a milestone of separator production size that can be used in one million EVs per year. Its production capacity will reach 2.73 billion m2 in 2024.

China’s EV market is the biggest in the world, taking up nearly half the global market. SKIET saw China’s marketability, and as their first overseas production base, they and started building plants in 2019.

Separators produced by SKIET are getting much attention in China. Even before the operation of Changzhou Plant 2, SKIET has already concluded supply contracts for the quantity planned for this year. This is because, with separators mentioned as one of the causes of frequent EV fire accidents recently, SKIET’s separators have not had any fire accidents so far, and thus brought the increase of customers wanting them.

SKIET is acknowledged for its incomparable technology in the separator industry. It’s leading the market through the technologies such as sequential stretching, Ceramic Coated Separators (CCS), etc., that can make premium separators.

According to the market research agency SNE Research, SKIET was ranked number one in the Tier 1 wet process separator market last year, with the percentage of 26.5%. Tier 1 refers to the automotive manufacturers leading the EV market such as Tesla, Volkswagen, Renault Nissan, Toyota, Hyundai Kia, etc. Tier 1 separator market is where separators are supplied to these companies. Only those who can produce high-quality separators are in this market, including SKIET, Japan’s Asahi Kasei, Toray, etc.

“By providing premium separators with both high performance and safety, we will contribute to the rapid growth of the global EV market and continue to improve the production capacity and technology to build an exclusive lead in the market,” said Roh Jae-sok, CEO of SKIET.

[Photos] Panorama view and front view of SK Hi-tech Battery Materials Jiangsu located in Changzhou, China

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin