SK Innovation

SK Innovation

SK Innovation decided to continue investing for the future despite the ongoing global economic downturn and the crisis caused by the COVID-19.

| SK Innovation’s decision to invest in its second EV battery plant in the U.S.

On April 28, SK Innovation announced its decision to additionally invest 727 million US dollars in the construction of a second electric vehicle (EV) battery plant in the U.S., following approval by the the firm’s Board of Directors.

In order to secure a stable supply of EV batteries for global automakers and boost its fundamental competitiveness in battery manufacturing business, SK Innovation said that it decided to inject a total of 3 trillion KRW for the two U.S. battery plants, among which the first one is currently under construction in Georgia, and the second one will be in the same state. In the long term, the company plans to scale up the investment, and it may be up to 5 billion US dollars.

This is SK Innovation’s Deep Change strategy to overcome the crisis with a bold investment amid the global economic downturn and the crisis caused by the COVID-19. This decision will lead to an expansion in the production base of electric vehicle batteries in the U.S., which is a major battleground for global automakers.

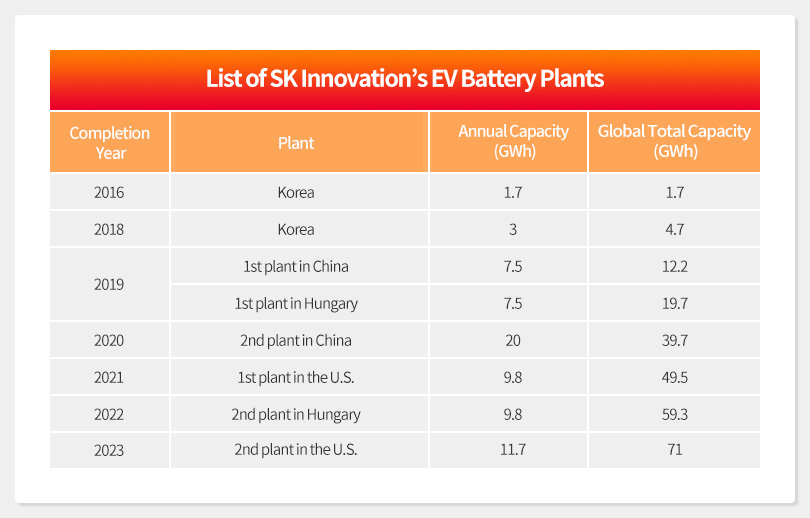

The firm plans to break ground its second battery plant in July this year. With an annual capacity of 11.7GWh, the plant is expected to go into mass production in 2023.

From 2023, when the first and second plants are in full operation, SK Innovation will be able to produce 21.5 GWh annually in the U.S. These local factories will help the company reduce logistics costs and secure a stable battery supply base for automakers in the U.S.

▲ SK Innovation’s first battery plant in Georgia, the U.S., is under construction

| SK Innovation’s expansion of production bases around the world and its target to become ‘top 3’ battery supplier

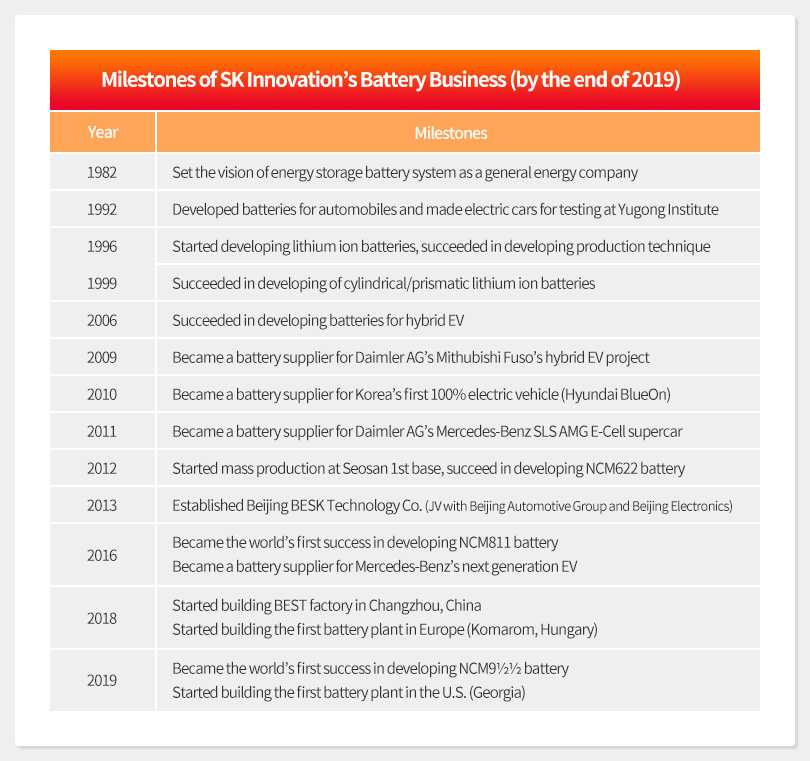

SK Innovation is expanding its battery production base at home and abroad. In Seosan, Korea, where its very first battery factory was established, the production base has expanded to the 7th facility. Thus, the company’s domestic production capacity now is 4.7GWh.

SK Innovation is also boosting its business in China, the fastest growing market for electric vehicles in the world. In 2013, the company established a joint venture, named BESK with Beijing Automotive and Beijing Electronics. In 2018, the joint venture broke ground for “BEST”, a state-of-the-art EV battery plant in Changzhou City, Jiangsu Province, with an annual capacity of 7.5GWh. BEST has been operating since the end of last year. Meanwhile in Europe, SK Innovation completed its first battery cell factory in Komarom, Hungary. This first plant in Komarom has the same annual capacity as BEST, and the construction of the second plant in Komarom has started after the first one began its production early this year.

▲BEST plant in Changzhou, China (Left), SK Innovation’s first battery plant in Komarom, Hungary (Right)

With its bold investments and constant efforts to expand its worldwide presence, SK Innovation expects to increase its current total global production level of 19.7GWh to 71GWh by 2023. The company aims to be one of the top 3 global players in the EV battery market, with the target of reaching 100GWh by 2025.

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin