SK Innovation

SK Innovation

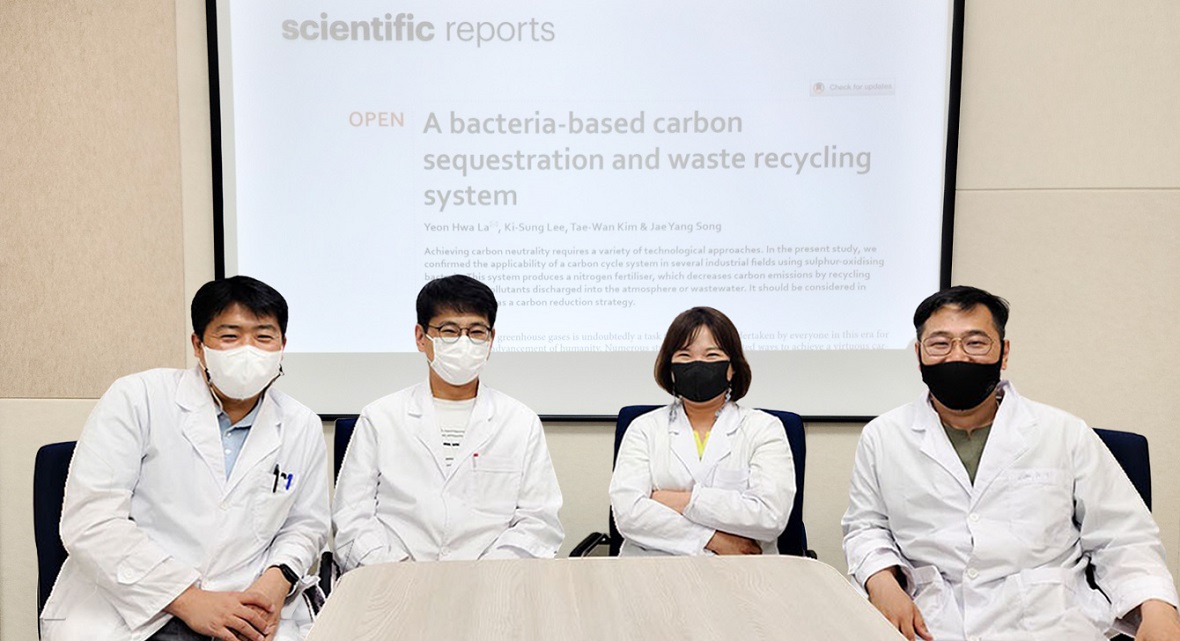

▲ From left: Kim Tae-wan, Song Jae-yang, La Yeon-hwa, and Lee Ki-sung, the authors of “A bacteria-based carbon sequestration and waste recycling system” study published on Scientific Reports on June 28, 2022.

On June 28, a study about the applicability of a carbon cycle system using sulphur-oxidising bacteria co-written by four researchers of Water Task in SK Innovation’s Institute of Environmental Science & Technology was published on Scientific Reports (a primary research publication from the publishers of Nature). Titled “A bacteria-based carbon sequestration and waste recycling system,” the study by La Yeon-hwa, Lee Ki-sung, Kim Tae-wan, and Song Jae-yang suggests a new solution that can effectively reduce carbon dioxide emissions, which is a critical issue especially in petrochemical industry.

As SK Innovation is accelerating the Green Transformation strategy in multiple aspects of its businesses, the publication of this study on Scientific Reports is not only a notable technical achievement but also the evidence of the genuine efforts of the company’s members to reduce carbon emission.

Let’s meet La Yeon-hwa researcher to learn more about the background and highlights of this project through our interview with her recently.

Q1. First, congratulations on the publication on Scientific Reports. We are curious about the background of your study.

SK Innovation’s Institute of Environmental Science & Technology is entrusted with a crucial mission of actualizing the Green Transformation, and among the many plans of action is the Carbon Capture and Storage (CCS) project.

We came across the bacteria-based reduction technology that makes use of sulfur, the by-product of our petrochemical factories, when we were searching for the technology to store and transform carbon, which is a stable substance with a low-energy level. Countless microorganisms exist in the world, and sulfur-oxidizing bacteria acquire chemical energy from sulfur and eat carbon dioxide to grow and prosper. In this process, the sulfur becomes a sulfate substance, and the ammonium solution is required to create the best pH environment for microbial growth. And the reaction of the two substances produces ammonium sulfate fertilizer. The existing ammonium sulfate produces sulfuric acid from sulfur under high temperature and high pressure conditions, and the process is complicated and requires much energy as it needs to be reacted with ammonia, which is produced with hydrogen and nitrogen. On the other hand, we thought that the same could be produced but in a more environmentally friendly technology, which is to make use of sulfur and ammonia. That’s why we started our research.

Q2. Could you briefly introduce some main points of the research?

The research studied the new resource circulation system that produces eco-friendly fertilizer and reduces carbon dioxide, using the chemical energy acquired from sulfur and bacteria. As for the new bacteria (Acidithiobacillus sp.), we were able to reduce carbon at the speed of 8.8-10.4 kg /m3/D in the continuous stirred tank reactor. And at the same time, we were able to produce 28-65 kg/m3 amount of fertilizer (ammonium sulfate). The application example of this technology would be the proposal of the virtuous carbon cycle that is going to be useful in petrochemical and anaerobic digestion industries that discharge reduced nitrogen or reduced sulfur.

In this study, the newly found bacteria, the sulfur-oxidizing bacteria (SOB), shows the fastest immobilization speed of carbon dioxide among the recorded bacteria until today, and its speed is 300 times faster than trees and 7 times than microalgae. Trees and microalgae require light energy for carbon dioxide immobilization, leaving with circumstantial limitations, such as environmental conditions. However, the process developed in our research utilizes a chemical energy source, allowing such a limitation to be overcome. Moreover, it shows high resistance to Sox and Nox that are discharged along with the carbon dioxide in air emission facilities, which means that it can be directly used in actual factory exhausts. The technology developed in this research has applied for five patents, and we are striving hard to make sure that our technology is differentiated from the rest.

Q3. What is the mainspring of the publication of this research on Scientific Reports?

In my opinion, it can largely be attributed to the research and development culture of SK Innovation’s Institute of Environmental Science & Technology, where it fiercely takes on challenges and is not afraid to make mistakes. Lack of reference was another obstacle as it was a brand-new concept technology, but each time we faced a problem in our studies, each of the experts with excellent technological capabilities of the team cooperated with one another to actively seek a solution to the problem. Moreover, such accomplishment was made possible by Head of the institute Lee Seong-jun, and Environmental R&D Center Officer Kim Tae-jin, who generously mentored and supported us throughout our studies. Every time we faced a technological difficulty, they rolled up their sleeves and sought solutions with us. Thanks to their instruction and guidance, we drew excellent results and earned recognition from the prestigious journal.

▲ From left: Song Jae-yang, La Yeon-hwa, Lee Ki-sung, and Kim Tae-wan, the authors of “A bacteria-based carbon sequestration and waste recycling system” study published on Scientific Reports on June 28, 2022.

Q4. What are your most satisfying and rewarding moments while doing this research?

That would be when the continuous stirred tank reactor was produced and finished its test run. The bacteria reactor available in the current market could not be used for our technology because it was suitable for normal pressure and mild pH conditions only. Moreover, we needed to select a special reactor and pump to improve the mass transfer through the complex reactions of solid, liquid, and gas. Everyone on the team, especially Dr. Jung Jae-heum and Dr. Kim Tae-wan, strove day and night, racking their brains to produce the reactor. However, when the shipping and test run were postponed due to COVID-19 and social distancing, everyone felt burdened and downcast. But when the normal operation finally took place after several trials and errors, I remember how I had butterflies in my stomach waiting for the outcomes.

Q5. Lastly, what are the plans and strategies of the Institute to reduce carbon?

Just as the Head of Institute Lee Seong-jun said, we aim to achieve Net Zero target by solving the carbon emission issue through the Green Transformation strategy that innovates the traditional carbon-based business model. On top of that, we seek to lead the global carbon-neutral efforts through Green Anchoring, through which we will do our best in the new growth-engine businesses, such as battery metal recycling (BMR) and plastic recycling. Moreover, we will efficiently provide technological support to all affiliates of SK Innovation while always staying focused on reaching carbon neutrality.

Read the study published on Science Reports: A bacteria-based carbon sequestration and waste recycling system

Youtube

Youtube Facebook

Facebook Instagram

Instagram Linkedin

Linkedin